146oly_TEMPORARY BRIDGE OVER THE RIVER BOW

Five months to the 2012 Olympic opening ceremony and a request to design a temporary 70m tidal river crossing within 14 days! Think of it as a design exercise though more 100m sprint than marathon. The salient point about ‘temporality’ is that it frees one from the strictures of permanence and the “built to last” culture. Sustainability? Not an issue? Aesthetics? Not an issue. Just build a temporary low-cost large-span pedestrian bridge in the shortest time possible for the least money. We don’t care what it looks like as the crossing is a 100-day event. Could we utilise the spirit of the Citizen Olympian? Could you too build a (Bailey) bridge!? Ready, set go: no time to waste even if Wikipedia is down!

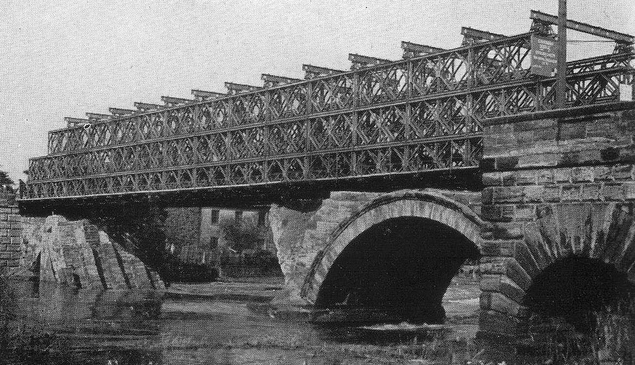

This could be a ‘triple triple’ Bailey timber construction made by citizen carpenters…

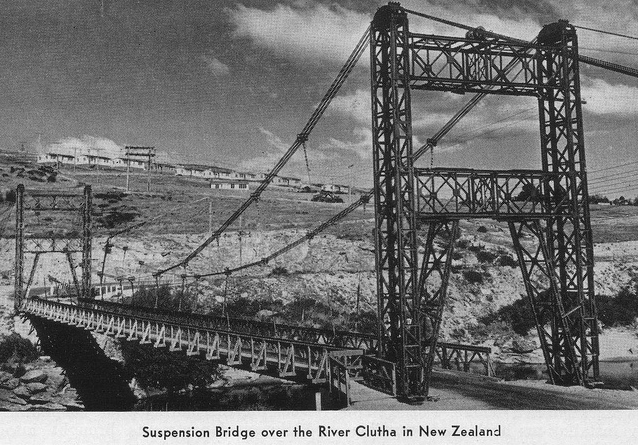

or a Suspended Bailey. Or should we look at an off-site pre-fab lightweight quad-laced truss? Or would we reduce the span with a tower crane providing mid/third-point cable stayed supports? The suspension is gripping… this is a bridge to where?

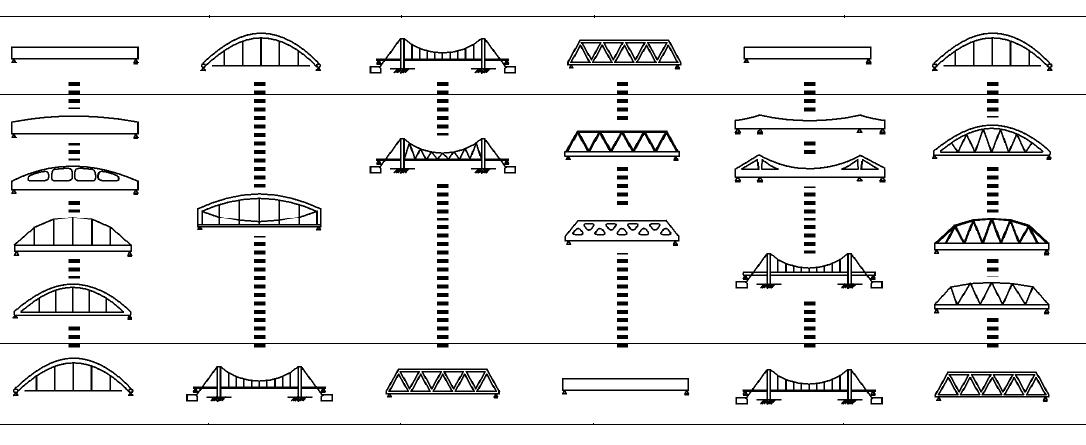

The evolution of large span structures typically manifest in bridge design suggests that this is an area of design where the architect, the artist, the hairdresser has been squeezed out by the engineer. However there is a participatory role here for the random Joe Public thanks to Yoshiaki Kubota’s systematisation of bridge types:  A wide range of otherwise unpredictable variations in form can be readily generated by combinations of simple rules e.g. add a brace, subtract a brace, subdivide a bay, shorten, lengthen, rotate. It is therefore straightforward to generate a multi-dimensional “design space” containing a myriad of options which a rational designer would never consider. The question is then whether any better designs exist within the space of possible bridge shapes, and Stephen Wolfram’s experience in other areas makes him believe quite strongly that they would. His other work also suggests they may look like nothing we have seen before, possible quite “random” in appearance.

A wide range of otherwise unpredictable variations in form can be readily generated by combinations of simple rules e.g. add a brace, subtract a brace, subdivide a bay, shorten, lengthen, rotate. It is therefore straightforward to generate a multi-dimensional “design space” containing a myriad of options which a rational designer would never consider. The question is then whether any better designs exist within the space of possible bridge shapes, and Stephen Wolfram’s experience in other areas makes him believe quite strongly that they would. His other work also suggests they may look like nothing we have seen before, possible quite “random” in appearance.

So let’s Ready, Set, Go!

Google “70m span pedestrian bridge” to start with and you get amongst ‘our’ competitors, this:

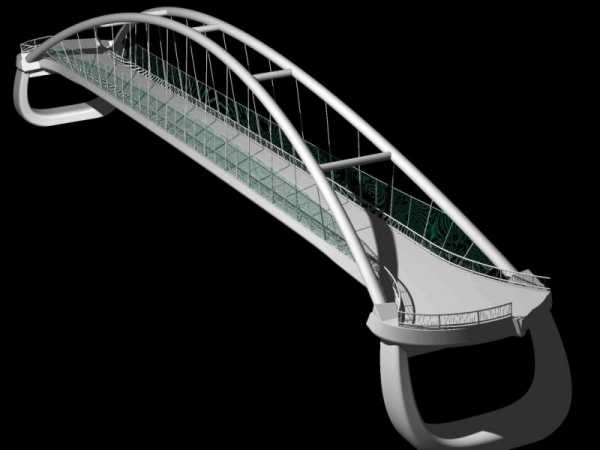

LANE 1: “a 95m span basket-handle arch spans across a freeway consisting of tubular steel arch ribs supporting a lightweight concrete post-tensioned edge girder deck.”

Blablablarchitecture summarises this as being cable stayed or suspension as the structural means, steel as the material means; but it looks expensive. Like a Philippe Starck toilet brush: could cost £1, can cost £187.50) However could we dismantle this idea and make a cheaper/popular assembly/low-tech version? WHAT_ would an Argos Basket Handle Arch look like?

Let’s try tackling the material means by trying to make a 95m span bridge in wood. Google ‘World’s Largest Timber Structure” and we get :

LANE 2: Mayer’s Metropol. Fanciful yes, now let’s run it through the Argos rinse…

Blablablarchitecture summarises this as being, well… let’s not’s spend time on its undoubted formal beauty but it suffers from the same reason as Lane 1: it looks expensive, therefore a bit slower… because it’s worth it. Apparently say Spainomics. We cross to…

LANE 3: TBC

SAY WHAT_!?

![1280480057_southease-pedestrian-bridge-rmd-kwikform's-longest-single-span-temporary-footbridge-2mr[4]](https://www.blablablarchitecture.com/blog/wp-content/uploads/2012/01/1280480057_southease-pedestrian-bridge-rmd-kwikforms-longest-single-span-temporary-footbridge-2mr4.jpg)